TERA-Fab® E series

Key Features

Experience the Power of E Light

Powered by an advanced light engine, TERA-Fab E series delivers light to a sample in multiple wavelength options. With an unrivaled uniformity across the projection area, TERA-Fab E series maintains precision even at higher intensity levels.

Pattern Without Limits

Create patterns and structures with diffraction-unlimited dimensions as small as 250 nm by operating the E series in the beam pen lithography mode or microscale resolution by using the machine as a maskless photolithography tool without a tip array.

High Throughput Without a Mask

Beam pen arrays comprise 10,000s of probes, each of which can be independently controlled with the light engine to write truly arbitrary patterns over square millimeter to centimeter areas in parallel.

Spend Time Printing, Not Aligning

TERA-Fab E series eliminates the tedious and error-prone alignment process from your experiment. With an accurate and precise automatic alignment routine, M series lets you set up and begin printing faster than ever before.

Uncompromised Nanoprecision

Built with a high-end piezo stage, the M series allows the user to print inks onto surfaces with exceptional consistency and reliability.

M series controls motion in <100nm step sizes across a 100µm range in three dimensions, giving you the ability to create features at any location over centimeter scale areas with supreme precision.

M series controls motion in <100nm step sizes across a 100µm range in three dimensions, giving you the ability to create features at any location over centimeter scale areas with supreme precision.

Nanofabricate Like a Pro

Simple and intuitive design of the hardware and software allows users of any experience level to begin nanofabricating in no time.

TERA-Fab OSe neatly packages all control parameters exactly where you need them.

Applications

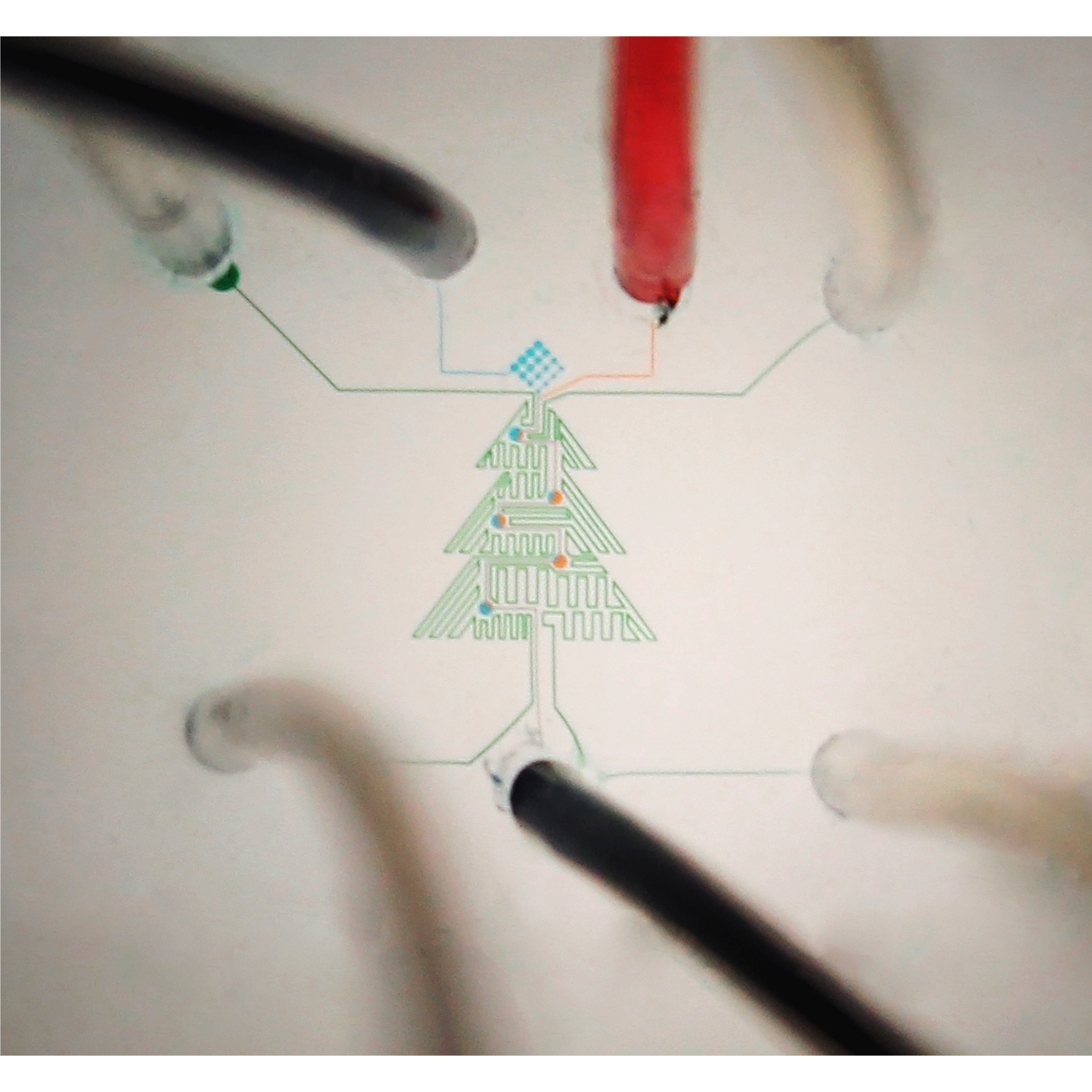

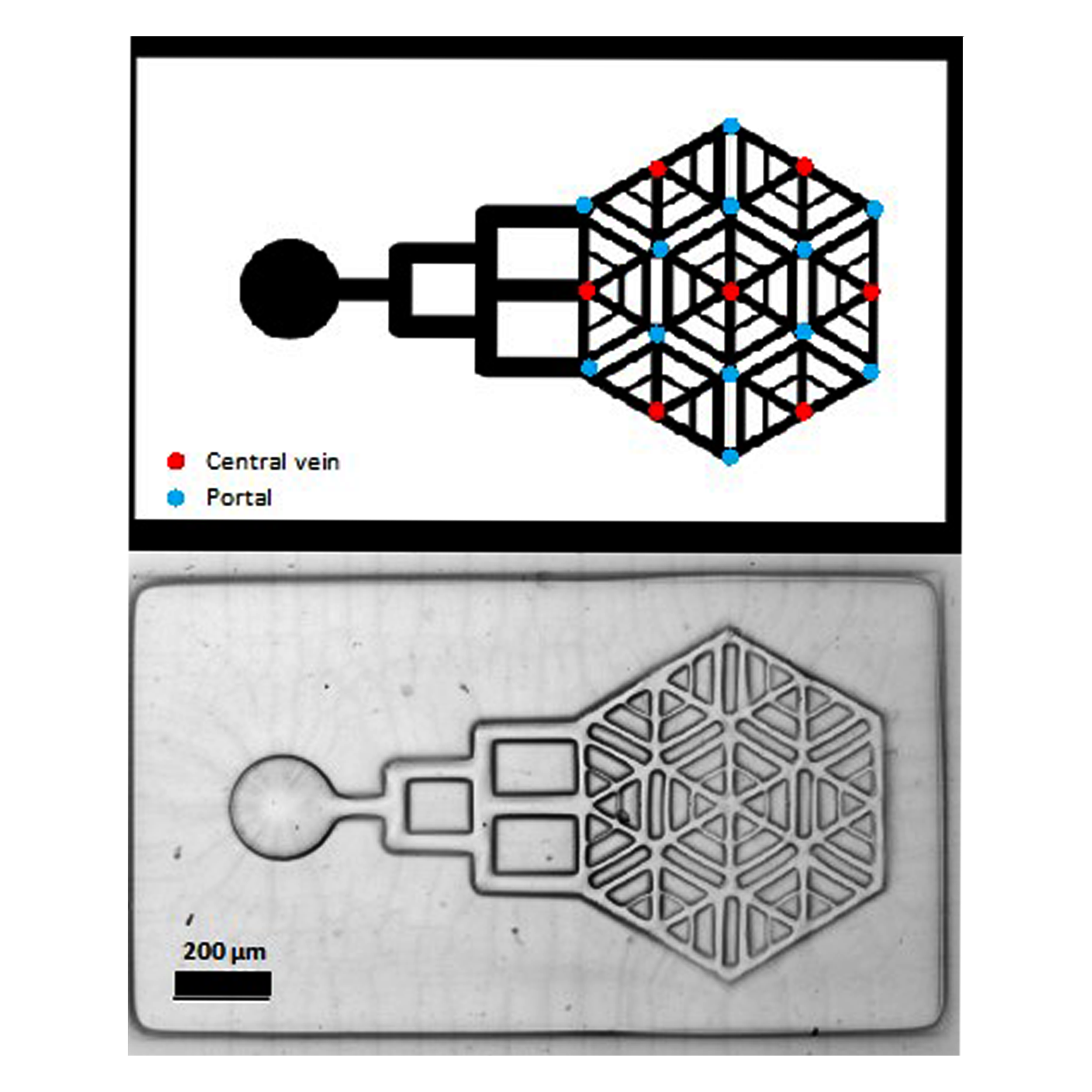

Microfluidic Devices

Rapidly design and fabricate microfluidic channel molds using conventional positive or negative photoresists outside of the cleanroom.

3D Bioprinting

Generate complex hydrogel scaffolds via ECM photo polymerization to create in vitro platforms with sub-cellular resolution.

Grayscale Lithography

Pattern complex features with varied depths using dynamic exposure and reduced light intensity.

Technical Specifications

Stage

Optics

Features

Software

| X-Y scan range (closed loop) | 100μm x 100μm typ., 95μm minimum |

| Z travel range (closed loop) | 100μm typ., 95μm minimum |

| X-Y-Z tolerance (closed-loop) | 1nm typ. |

| Repeatability | <10nm typ. |

| Manual X-Y positioning stage | 12.7mm x 12.7mm travel range |

| Motorized Z axis | 12mm travel range, bi-directional repeatability, 0.75μm bidirectional repeatability, 2mm/s maximum speed |

| ΘX and ΘY 2-axis angular positioning | ±3.5° angular range, 4x10-5° angular resolution |

| Motorized X-Y motion | 50mm x 50mm travel range, bi-directional repeatibility: 1μm |

| Motorized Z motion | 50mm travel range, bi-directional repeatibility: <50μm, maximum speed: 3.0mm/s |

| Digital LightProcessing (DLP) | DLP5500 0.55" XGA Chipset, 1024 x 768 resolution |

| Light Sources | UV LED Light Engine (405nm) 2.4-2.8W, Green LED Light Engine (532nm) 2.5W, additional 460 and 365 options available |

| 5x Objective M Plan APO | 34mm working distance, 2μm resolving power, additional objective lenses available (10x, 20x, 50x) |

| Field of View | 1.28mm x 0.96mm |

| CMOS camera | FLIR 12 MP (4000 x 3000) CCD, 0.74cm x 0.55cm sensor size, 1.85μm x 1.85μm pixel size |

| X-Y-Z piezo scanning stage |

|

|

| Z positioning of sample stage |

|

|

|

| Stage leveling |

|

|

|

| Patterning |

|

|

|

|

|

| Optics |

|

|

|